Electrical Switchgear

Allow manufacturers to create a comprehensive database of information for their entire portfolio of installed equipment & offer predictive maintenance services to ensure that transformers and switchgear are operating reliably

Electrical Switchgear suppliers face a number of challenges:

- Lack of access to equipment in use means suppliers only have a limited understanding of its behaviour and field performance.

- The need for swift response to alarms as they are always extremely high priority; although problems with transformers and switchgear are infrequent, they cause serious business interruptions when they do occur.

- Finding the optimum price point for quality equipment and services.

- Finding ways to enhance services and increase customer satisfaction.

- Optimising routine maintenance so as to avoid revisits.

- Identifying the cause of any problems, the best solution and locating the closest possible support crew to send to the site.

Pacific Controls Managed Services for Electrical Switchgear

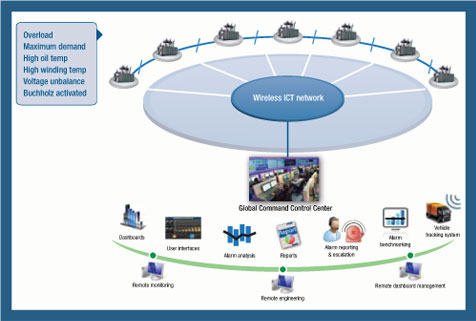

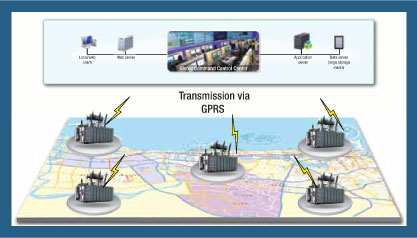

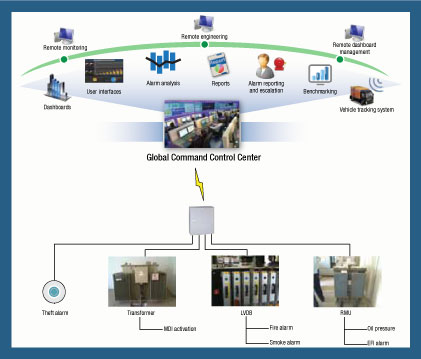

Using Pacific Controls ICT Enabled Managed Services for Business Process Integration, suppliers can connect transformers and switchgear anywhere in the world to the GCCC. Pacific Controls’ M2M data panel is installed alongside the equipment in order to transfer data from proprietary systems at the site onto the IP network for transmission to the GCCC or integration with the manufacturer’s own enterprise management software. This approach gathers real-time information to be collated on a cloud-computing platform and accessed from any location using any web-enabled device. It will enable service teams to receive real-time alarms, along with detailed information about the faults and automated monitoring data for the entire portfolio of installed equipment.

Real Time Monitoring and Management of Electrical Switchgear

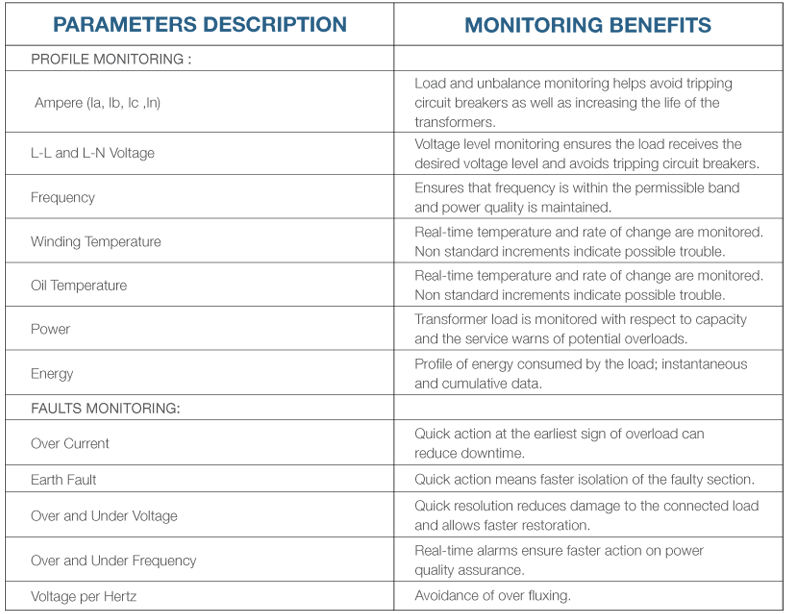

The managed services are designed to monitor and control the transformers in real time, using state-of-the-art technology to provide the same user experience on a web browser as that of a standalone windows application. The main screen shows all of the transformers and switchgear the user is monitoring in one view, alongside live performance data. Any number of ‘use cases’ can be defined for different types of equipment and any parameter outside defined limits can trigger an alarm. The transformer’s details are accessible only to authorised users and authorisation is set by the administrator. At the top of the alarm-monitoring screen are shown various useful reports, while hovering the mouse pointer over an alarm shows additional information. The table below shows some typical parameters used for monitoring the health of transformers. The service proactively indicates where problems may be developing and suggests ways to avoid them by taking timely action.

Benefits for Electrical Switchgear Manufacturers

Pacific Controls ICT Enabled Managed Services For Business Process Integration allow transformer and switchgear manufacturers to create a comprehensive database of information for their entire portfolio of installed equipment. The system unifies the data, making it comparable, and uses artificial intelligence, data mining techniques, trend prediction and modelling to deliver meaningful results in a range of dashboards and reports. The service brings long term benefits as it will assist in delivering higher value to the customers and position the product in a premium quality market space.

Using Pacific Controls’, transformer and switchgear manufacturers can offer their customers monitoring and management services through a single interface that connects all the equipment they have deployed. This allows them to have an on-going relationship with transformer users and provides a central data depository for analysis that will enhance R&D.

Manufacturers can also offer predictive maintenance services to ensure that transformers and switchgear are operating reliably, with little or no downtime.

Benefits for Electrical Switchgear Users

For users of electrical switchgear, equipment reliability and switchgear life is significantly increased. Power cuts cease to be a problem, while overheating and potential fires are entirely eliminated.