Power Generation

System provides suppliers the tools for centralised monitoring of all the generator sets in use with access to real-time data from any location allowing remote trouble shooting

Proactive Monitoring Ensures Generators Start When Needed

Many critical locations rely on generators as back-up power supplies, including hospitals, oil and gas sites, telephone exchanges, data centers and financial institutions. However, as the equipment is only used rarely, there is always a risk that the generator will fail to start up when it is required, causing serious problems and inconvenience. Modern generators have digital control systems that are compatible with ICT and can be monitored and tested remotely, and fuel supplies checked, using Pacific Controls’ Managed Services for Critical Assets Monitoring.

Facility managers need real time status information for generator sets, including monitoring of performance parameters, battery levels and fuel supplies. They need notification of alarms by email and SMS, event history logs and alerts, performance benchmarking and analytics and reports on generator status, performance and alerts. Problems commonly encountered with backup generators include failure to start because the battery is flat or the engines are worn, which also leads to inefficiency. Regular testing and maintenance are essential.

Pacific Controls Generator Monitoring System

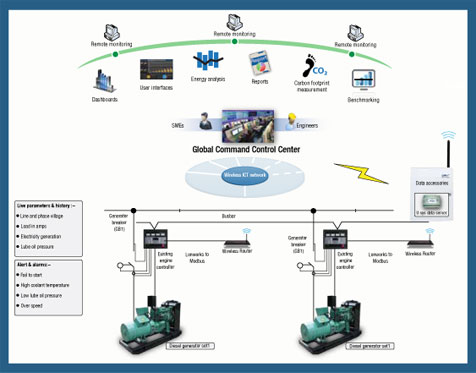

Pacific Controls ICT Enabled Managed Services For Business Process Integration provide a management information service that generator manufacturers, or suppliers of rented generator sets, can use to gather real-time information about the status of their equipment as it is used. It also automates the processes of testing and re-fuelling. It therefore allows them to offer additional value-added services to the generator users.

Sensors and controllers are installed, with a data gathering panel alongside the generator set that will push the data over the general packet radio system (GPRS) to the GCCC. This data can be accessed by authorised users at any time from any location and from any web enabled device. It is not dependent on a fixed PC in one location. The Pacific Controls team maintain the application and hosting infrastructure and support the suppliers’ staff in using the service.

Generator Management Software Suite

The following key alarms and monitoring points will be set up in a standard installation but this can be amended to meet the user’s requirements:

- Engine status

- Coolant temperature

- Bearing and winding temperatures

- Oil pressure

- Running hours

- Fuel level

- Electrical parameters including: voltage, amps, kW, power factor

- Fault alerts.

An alarm console shows the real time alarms and alerts received from the generators, with full details. Traffic light colour coding shows at a glance which alarms have been normalised and which are still active. Each alarm or alert can have website and graphics links associated with it to help with troubleshooting. Each user can be shown the alerts from any number of facilities. The alarm console is used to display the alarms to the operators, to track their status, record the alarm history and to generate management reports.

Benefits for Generator Suppliers

Pacific Controls Managed Services for Critical Assets Monitoring provide suppliers with the tools for centralised monitoring of all the generator sets they have in use, giving them access to real-time data from any location and allowing remote troubleshooting. This reduces the cost of maintenance contracts and allows them to respond quickly to any alarms. It allows them to offer refuelling services and SLAs for equipment reliability.

Benefits for Generator Owners

End users gain peace of mind from knowing that the generator set is being maintained so that they can be sure it will start when needed, as well as gaining from a reduction in operations costs, more efficient power delivery and an increase in equipment life.