Busbar Power Distribution

Suppliers can offer their customers monitoring and management services & emergency call-out services to ensure that power is restored rapidly in the unlikely event that a breakdown does occur

Manufacturers of high and low voltage systems for power distribution in factories, workshops, assembly lines, warehouses, transport terminals, data centers and supermarkets can use the Pacific Controls ICT Enabled Managed Services for Business Process Integration to monitor their customers’ busbar systems. The service can monitor electrical performance and heat distribution in high voltage metal-clad switchgear, low-voltage switchgear, cast resin transformers and panel boards. A fault or failure in any one of these components can result in power outages, loss of productivity and even fire or explosions; so building owners are keen to ensure they are protected.

Busbar Protection must be Accurate and Respond Swiftly

Busbars have often not been given their own specific protection because they are highly reliable and because any accidental activation of the protection mechanism might cause more problems than the faults triggering the activation. This is not a good policy because the damage resulting from one uncleared fault can be severe and, in the worst case, overheating of a busbar may cause a fire. In many cases, electrical supply protection is applied only to feeders and plant, in which case the busbars are not always inherently protected. However, the protection scheme needs to cover the whole system against all probable types of fault. Unrestricted forms of line protection, such as overcurrent and distance systems do provide this, but lead to delays in clearing faults in the busbars. To maintain system stability, and avoid tripping circuit breakers elsewhere in the system, protection must be fast, which can only be provided by systems specifically designed for the busbars. Typical fault clearing time should be less than 100ms; with fast breakers this means measuring time should be of the order of 20 to 30 ms.

The risk of an unnecessary trip must be kept to a minimum. Mistrips must be identified accurately, and are often caused by faults just beyond the zone of busbar protection (commonly known as through faults).

In order to minimise the interruption to the plant, the protection system must correctly identify the area of the fault and open only the necessary and minimum number of breakers. To achieve this, it must discriminate properly. However, because of speed requirements, discrimination based on time delays is not acceptable. It is therefore preferable to have a clearly defined zone of protection or unit scheme.

Traditional busbar protection relied on logically structured arrays of relays. Modern ICT controlled busbar protection has two big advantages over these systems:

- Fewer external components are required as the functions of the relays are performed by the software

- Sophisticated monitoring that raises alarms if there is a fault. Using simulations, the operation of the protection system can be checked on a regular basis to ensure it is fully operational.

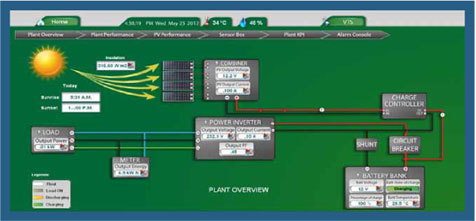

Pacific Controls Managed Services for Busbars

Using Pacific Controls ICT Enabled Managed Services for Business Process Integration to monitor busbars will identify critical hotspots and warn suppliers and system owners of overload, phase imbalance, low power factor, corrosion and poor electrical connections, all of which generate heat, waste power and can shorten the life of the equipment by up to 85%. Gbots using non-contact infrared sensors can identify these conditions, whether they develop slowly over time or result from a catastrophic fault. Services available include continuous temperature measurement to provide both instantaneous alarms for fault conditions and trend analysis for predictive maintenance.

Predictive maintenance is a most effective tool to prolong the life and efficiency of the equipment and to minimise shutdowns. Temperature monitoring, combined with load data, produces a real time thermal map and that is used to improve operator and facility safety, including prevention of arc flash incidents.

Pacific Controls Managed Services for Critical Assets Monitoring provide ‘anytime anywhere’ access to continuous online monitoring of busbar performance and reporting of consumption trends by connecting the protection systems to the 24x7 GCCC. The GCCC measures actual performance and benchmarks it against essential busbar parameters and international standards. Real-time Delta T temperature measurement can be captured and monitored. Any alarms are sent to the GCCC, which instantly reports any faults or emergencies and forwards details to the relevant personnel, and the service provider, via SMS or email. Alarm status is monitored to ensure there is an immediate response.

The service provides a centralised information depository in which a detailed history of operational parameters is stored and artificial intelligence identifies trends that can be used to schedule pre-emptive maintenance. This information can be used to identify strategies to optimise performance and increase the lifetime of the equipment. Proactive maintenance ensures an accurate and prompt response to faults and real-time information is available for informed decision making. For example, to identify hotspots and recommend alterations to the power distribution scheme to prevent future overheating.

Pacific Controls Gbots aid in optimising the performance of busbar protection systems. Gbots are a family of system management and customer support software tools; autonomous software agents which observe and act upon device, equipment and system behaviour. Gbots are enabled by ‘self-learning’ software agents installed in devices and equipment and implemented as a managed service. These agents or ‘bots’ are able to sense conditions, such as temperature, understand the levels the user specified and identify problems such as a busbar overheating or the electrical system being overloaded. They can repair some faults remotely and initiate actions to optimise system performance.

The GCCC has facilities to monitor all aspects of a building and its management systems, so busbar protection can be integrated with holistic building management. This allows loads to be reduced if overheating should occur.

Benefits for Busbar Suppliers

Using Pacific Controls Managed Services for Critical Assets Monitoring, suppliers of busbars can offer their customers monitoring and management services that allow them to have an on-going relationship with their users. These are delivered through a single interface that connects all the power distribution equipment they have deployed, whether in factories, data centers or tower blocks.

They can offer predictive maintenance services to ensure that all their equipment is serviced before it breaks down and that recommendations for reconfiguring power distribution are acted on before a busbar suffers serious overheating. They can also offer emergency call-out services to ensure that power is restored rapidly in the unlikely event that a breakdown does occur.

The cost of delivering maintenance services is reduced through the use of Gbots for remote maintenance and response to faults and through scheduling pre-emptive maintenance rather than having to respond to emergencies. Collecting information from all their equipment in one location provides a central data depository for analysis that will enhance R&D.

Benefits for Building Owners

Remote and real-time monitoring from the GCCC means that any problems in building systems are identified early and and facilities managers are provided with information on the actions needed to resolve them. There is a fast response to emergencies and power outages to ensure business continuity. Maintenance costs are reduced through more efficient scheduled preventive maintenance and the elimination of emergency call-outs. Busbars last longer because overloads are avoided and the cost of replacement is reduced because there is no need to over specify their capacity. The facilities manager and senior staff are provided with automatic reports on the condition and performance of their equipment.