Marine Applications

Integrates Marine Vessel Monitoring tool throughout the business ensuring single point of information & increases Marine Vessel health management and tracking operations efficiency through automation

Marine industry’s objective is to offer best possible updated technology for offshore services by adopting solutions that marine users to experience by proactive and predictive maintenance management practices.

ICT Enabled Managed Services for Marine Vessels

Pacific Controls has been recognized for developing various automation software and hardware, and deploying Global Control Command Centre (GCCC) for the ongoing commissioning of equipment and systems. Pacific Controls has been highly successful in implementing integrated automated solutions in the Government and commercial sector. Through its disruptive technology implementation the company has enabled customers to reap the benefits of remote control and integrated automation systems, and maximize the value of time-sensitive information.

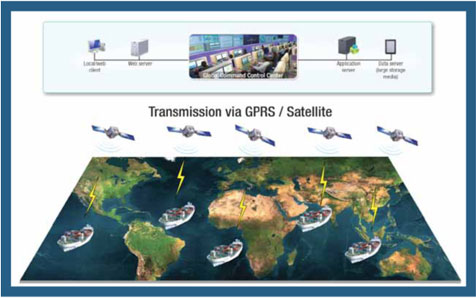

Pacific Controls ICT enabled managed services model for marine industry and assist in bringing higher value driven marine industry space achieved by data unification and building an extensive model on top of it to deliver results as managed service format. Adopting vendor neutral approach Pacific Controls in these projects integrate equipment using available possible interface. These integrations will be done at the site end and the critical data and information will be transmitted via cellular / satellite to central monitoring system to be processed by enterprise management software.

System Architecture

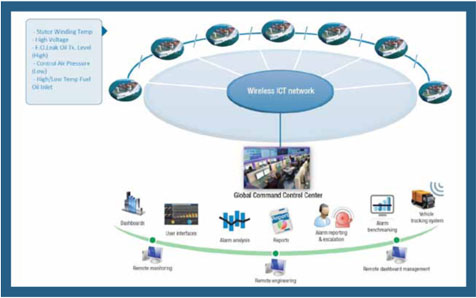

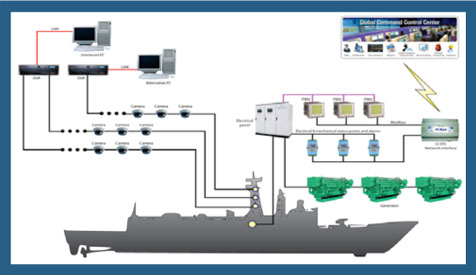

Pacific Controls has designed a unique cloud based solution where in controllers will be installed at site for marine vessel systems monitoring that will push the data over cellular / satellite to a Global Command Control Center. Global Command Control Center team will deliver the web-based solution to maintenance and support team and will maintain the application and hosting infrastructure. This architecture delivers an anytime anywhere access to operations and management team without dependency on a fixed PC in one location.

Following is the indicative system integration architecture while various components are shown that forms the schemes for Marine Vessels integration.

Value Proposition

Offered solution can deliver the following benefits to marine management team:

- Integrates Marine Vessel Monitoring tool throughout the business ensuring single point of information.

- Increases Marine Vessel health management and tracking operations efficiency through automation.

Galaxy will capture live information on operation, performance, efficiency of each marine vessel system and will also trigger immediate alarms on faulty equipment (e.g. tank gauges, pump performance, gas detection) and can help anticipate failure.

Such a solution yields immediate cost reductions in maintenance, optimizing resources on routine and nonscheduled interventions, as well as increasing up time, bringing significant cost savings to ship owners.

Marine Vessels Real-Time Monitoring And Management

Being able to sort problems out remotely is very important to improve the uptime of vessels to avoid costly delays when waiting to get things fixed. The managed services are a bundle of applications used to implement multiple use cases in managing performance of Marine Vessels “live”. Application is built on state of the art technology to provide the same user experience on a web browser as that of a standalone windows application.

The proposed monitoring system shows the listed marine vessel- equipment parameters in one view and shows its live performance monitoring. The Marine Vessels’ details are accessible only to authorized users and this authorization is set by the administrator. Above the alarm monitoring, system also generates various useful informative reports.

Parameters based on the available monitoring system can result in monitoring vessel health as well as proactive indication on possible trouble that can either be avoided or a timely action can be taken. If we can see a potential issue, we can inform to various stakeholders before they have even realised the problem onboard.

Scope of the Solution Marine Vessel Monitoring Software Suite

Marine Vessels will be connected with a real time alarm reporting controller and over Cellular / Satellite and will transmit the alarms to a centralized control and command center. The proposed solution is with integration of alarms and real time parameters from these Marine Vessels and reporting it back to management team by central monitoring system.

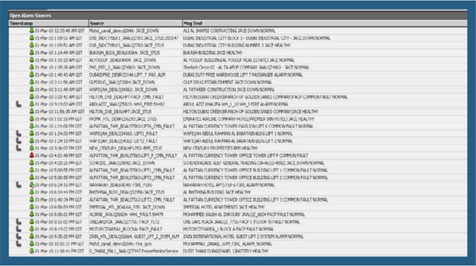

For operational management an alarm Console is designed to facilitate user to view the Real Time Alarms and Alerts generated from the Marine Vessels. It also gives the details of the alarm or alert with description. It gives a traffic light indication to make it more user-friendly so that by having a glance at it can provide a clear picture whether the alarm has normalized or still active.

The purpose of having an alarm console is to define the processes to effectively implement and manage an alarm system for assets. The alarm console is used to display the alarms to the operators, track status, record history and generates alarm metric reports

Key Features

Keeps the track of Real Time Alarms/ Alerts

- Active and non-active alarms can be easily distinguished

- Different users can be related to single or multiple facilities

- Each Alarm/Alert can have its own Website links and Graphics Link associated with it that could help in troubleshooting an Alarm/Alert.

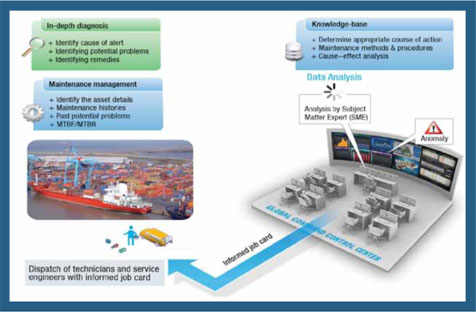

Galaxy Expert Rule Engine System for FDD

The ever increasing complexity of business data systems is demanding a smarter, more intelligent means of fault detection and diagnosis. Galaxy solution meets this need with its expert rule engine system which dramatically reduces dependence on human intervention and minimizes error in fault analysis. Its ability to learn from experience ensures that no abnormal equipment behavior goes unnoticed.

Fault detection and diagnosis (FDD) is crucial to maintaining Asset management systems at their optimal performance and reliability. The predictive intelligence of the software identifies processes in which performance is degrading and takes timely preventive action. The Galaxy FDD module provides proactive monitoring via the web in real time. It uses rule-based artificial intelligence to detect and identify faults, perform fault analysis and provide diagnostics reports. Galaxy’s FDD tools can actively simulate or test for faults under a complete range of operating conditions in order to understand faulty operation, what is causing performance to degrade, and identify broken components in a physical system.

Its key functions are:

- automatic collection and archiving of control systems data

- providing a configurable expert rule engine system for fault and event analysis

- managing performance metrics and monitoring KPIs, especially production and consumption

- fine-tuning of equipment as part of the continuous commissioning process.

The configurable rule engine is an expert system that captures the knowledge of a human expert by encoding it in to a rule set. The artificial intelligence (AI) in the system is then able to perform in a similar manner to the expert. This allows the expert system to make decisions and take action automatically in real time.

The rule engine provides:

- Knowledge representation: The human calculations for diagnoses of a fault are translated into a declarative programming language.

- Segregation of data and logic: The logic rules are segregated from the variable data into a central rule definitions repository.

- Configuration: with intuitive user interfaces for easy rule definition.

- Change management: ensuring rules are altered in a controlled manner.

- Self-learning: improving diagnosis over time through automatic learning.

- Reporting: faults detected are reported with a diagnosis.

The system can automatically take action to:

- Identify a fault

- identify the causes of the fault

- identify degradation in the performance of equipment or systems

- provide advisory service and support information

Data Mining Application

The Data Mining tools can be used to identify patterns in data. They can apply a rules based analysis and a wide range of techniques including a number of different types of regression, neural networks and clustering to predict future trends. They offer a wide range of data visualization methods to aid decision making. There are modules for fraud detection and revenue assurance.

Galaxy’s powerful data mining tools allow predictive maintenance – when equipment performance starts to degrade an alert is raised so that the unit is serviced before a breakdown occurs.

Prediction and Regression Analysis

This capability of is one of critical feature in Galaxy Information Management Delivery Systems inform of ability to predict values with reasonable accuracy. This is used for creating budgets or benchmarks for the present as well as the future. With the toolset available in Galaxy, it is possible to generate values for the future. With the predictive modeling engine, predictive tasks can be standardized and automated.

The predictive modeling engine will contain the following features:

- Iterative regression - Linear (with one breakpoint), multivariant linear and polynomial regression. Once the model is saved, it is recalculated if a period of recalculation is defined.

- Baseline adjustment – To define targets.

- Output of regression equation as a library or as a calculated point.

- Creation of test dependent variables through simulated meters that support entry for future values.

- Manual inclusion/exclusion of data points to prevent skewing of model due to anomalous data.

Anticipated Benefits

M2M technologies is a key part as an emerging trend in which embedded smart devices are networked wirelessly, allowing devices to talk to each other as well as respond to instructions from a user. A management layer sits between the user, who sets general targets, such as the required data or a destination, and a complex monitoring system that interacts with the devices to achieve them.

Following stakeholders in the organization are beneficiary of Pacific Controls Managed Marine Services Solution:

- Operations and Engineering

- Finance and Commercials

- Customer Support Services

- Sales and Marketing

- Corporate Social Responsibility

By using its unique business model, Pacific Controls has broken the cost barriers to access the proprietary and legacy data from all the different equipment and systems that assist to measure, monitor, and control to deliver optimum operations model.